Product

Eliminate secondary operations: A tube laser can cut a piece to length and add holes and other cutout designs in a single step, eliminating the need for secondary actions and manual material removal. You gain the ability to hold tight tolerances on more complex fabrications. Parts can be produced from one continuous piece of raw material to ensure that they only fit one way and are easily assembled. We can tube laser aluminum, stainless steel and carbon.

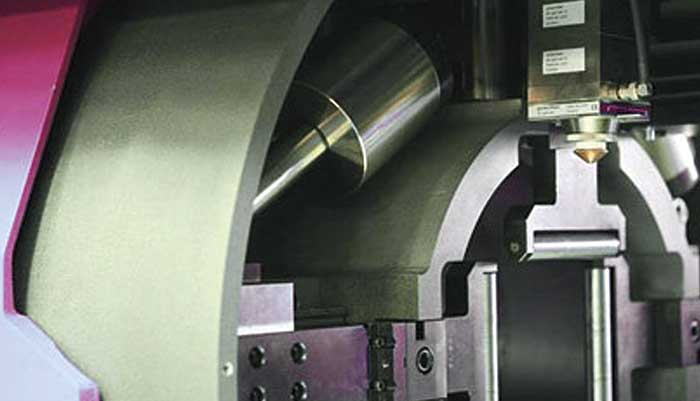

Sheet laser cutting is a complex process that requires material loading and unloading automation. There are many solutions available. Tube laser cutting systems with vertical storage systems for tubes and section bars that can automatically handle bars and allow for unmanned production changes, on the other hand, have only been around for a few decades.